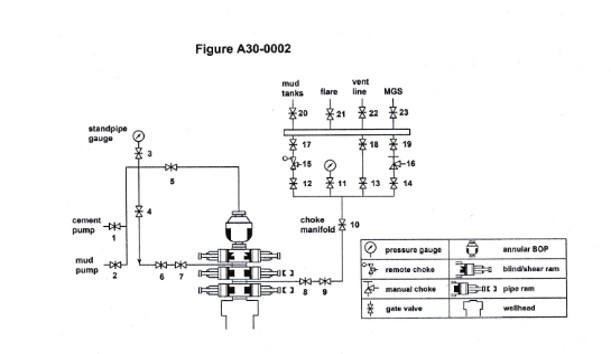

Figure A30-0002 shows a typical piping schematic for a surface BOP installation. The well is shut in on the annular BOP.

Mud will be circulated from the mud pumps through the drillstring and bled off through the remote choke to the mud tanks. Which groups of valves must be open?